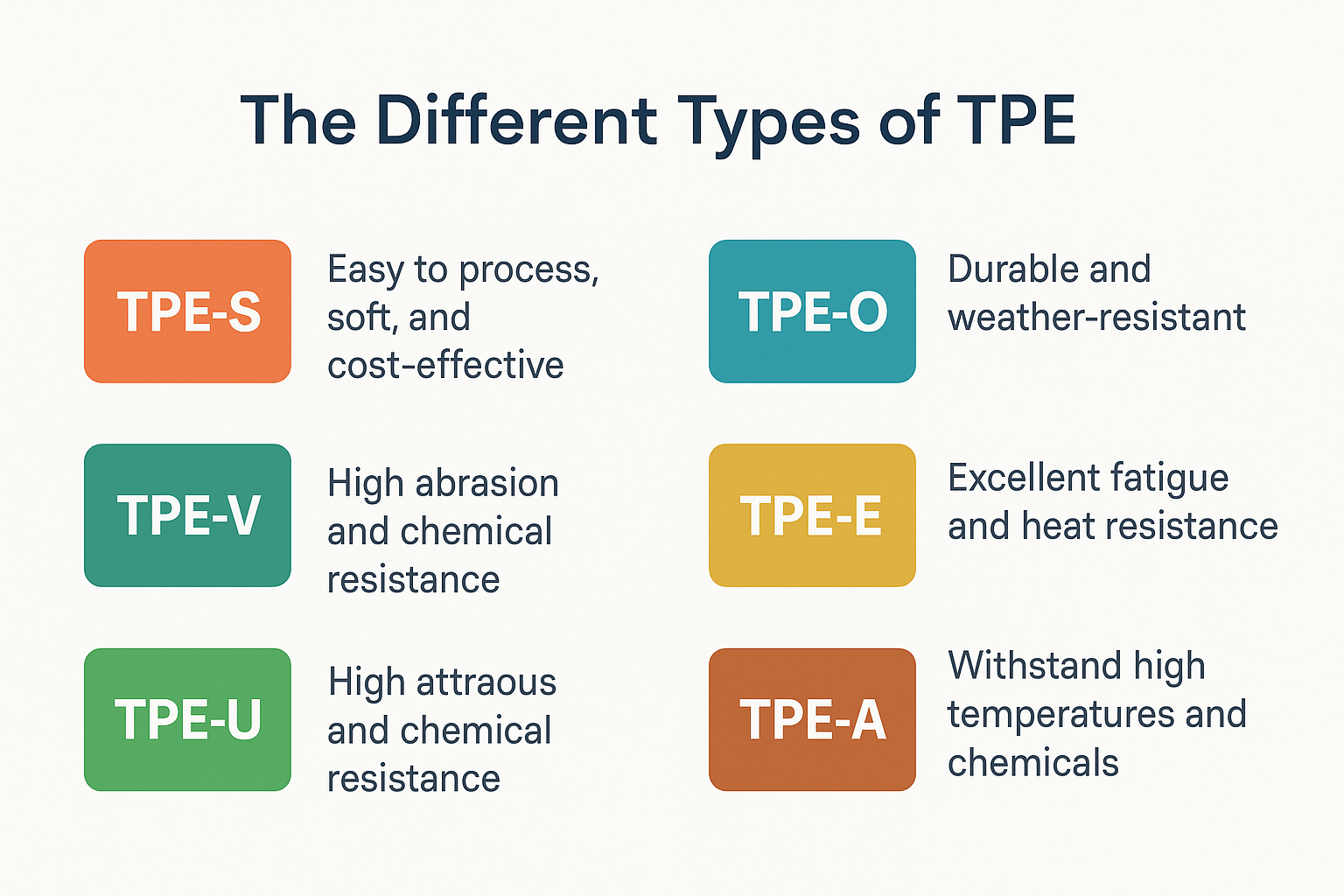

Thermoplastic elastomers come in various classes, each offering specific properties suited to different performance needs. The choice of base polymer largely determines a TPE’s behavior in terms of flexibility, strength, and resistance.

- TPE-S (Styrenic Block Copolymers): Easy to process, soft, and cost-effective. Common in grips, toys, and seals.

- TPE-O (Polyolefin Blends): Durable and weather-resistant, ideal for automotive and cable insulation.

- TPE-V (Thermoplastic Vulcanizates): Offers rubber-like durability and is often used in under-the-hood parts.

- TPE-U (Polyurethanes): Known for high abrasion and chemical resistance; used in footwear and hoses.

- TPE-E (Copolyesters): Excellent fatigue and heat resistance; often found in mechanical components.

- TPE-A (Polyamides): Withstand high temperatures and chemicals; used in demanding industrial applications.

Each type responds differently to processing methods like injection molding or extrusion, so selecting the right grade is critical for achieving reliable results.

Understanding these variations helps ensure the best material is used for both functionality and cost-efficiency.