Discover our Products

Learn about our products and find the ideal solution tailored to your needs.

Our Production Line

Explore our facility and experience firsthand how our innovative processes bring high-quality products to life.

Industries Served

Explore how our products deliver value across diverse sectors.

At MAK Sohar chemical industries LLC, we are pioneers in the chemical industry, driven by innovation, quality, and sustainability. With decades of expertise, our team specializes in developing and manufacturing high-performance chemical solutions that power industries around the globe.

Discover Our Products

Experience German Innovation in Polymer Manufacturing

TPE

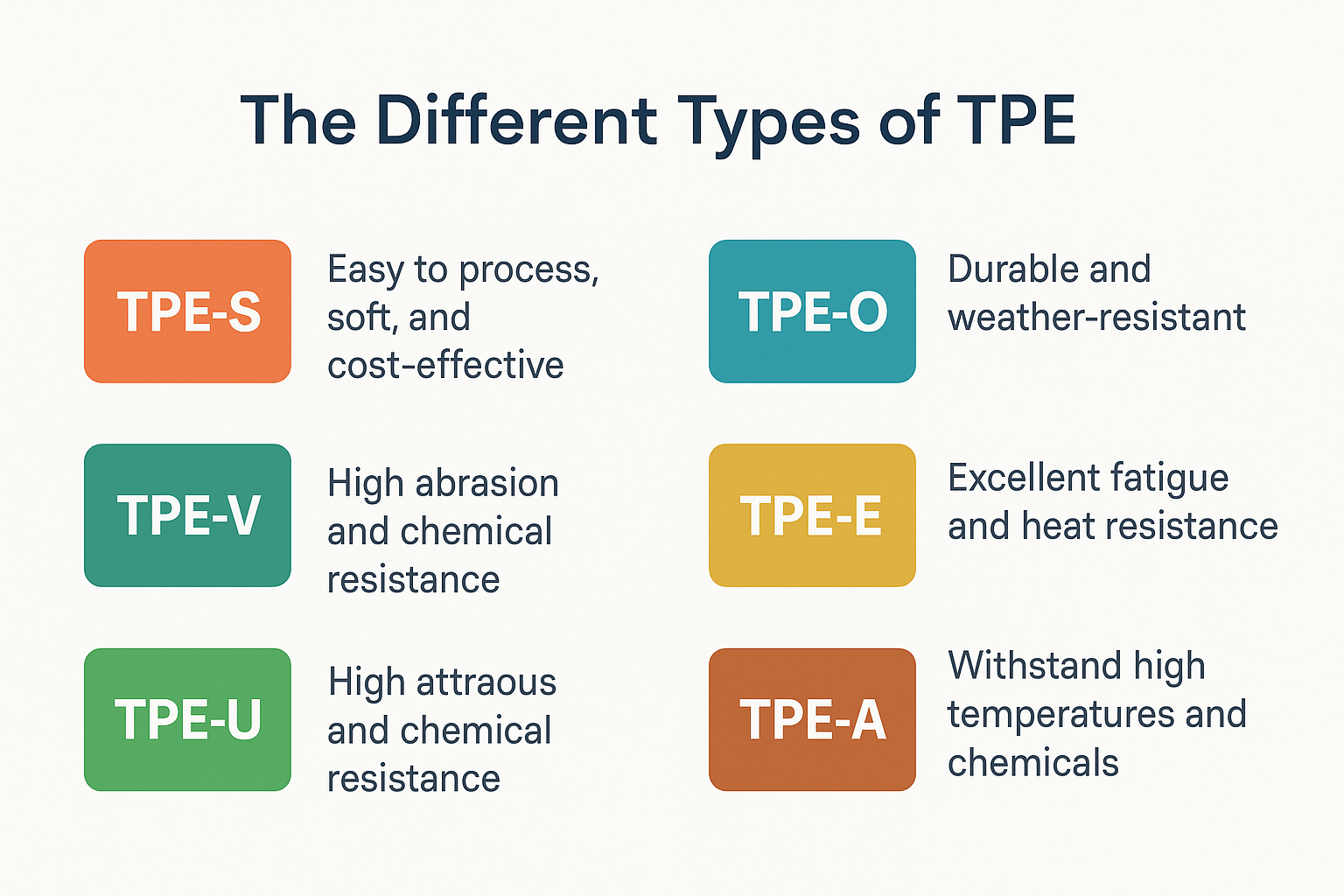

About TPE

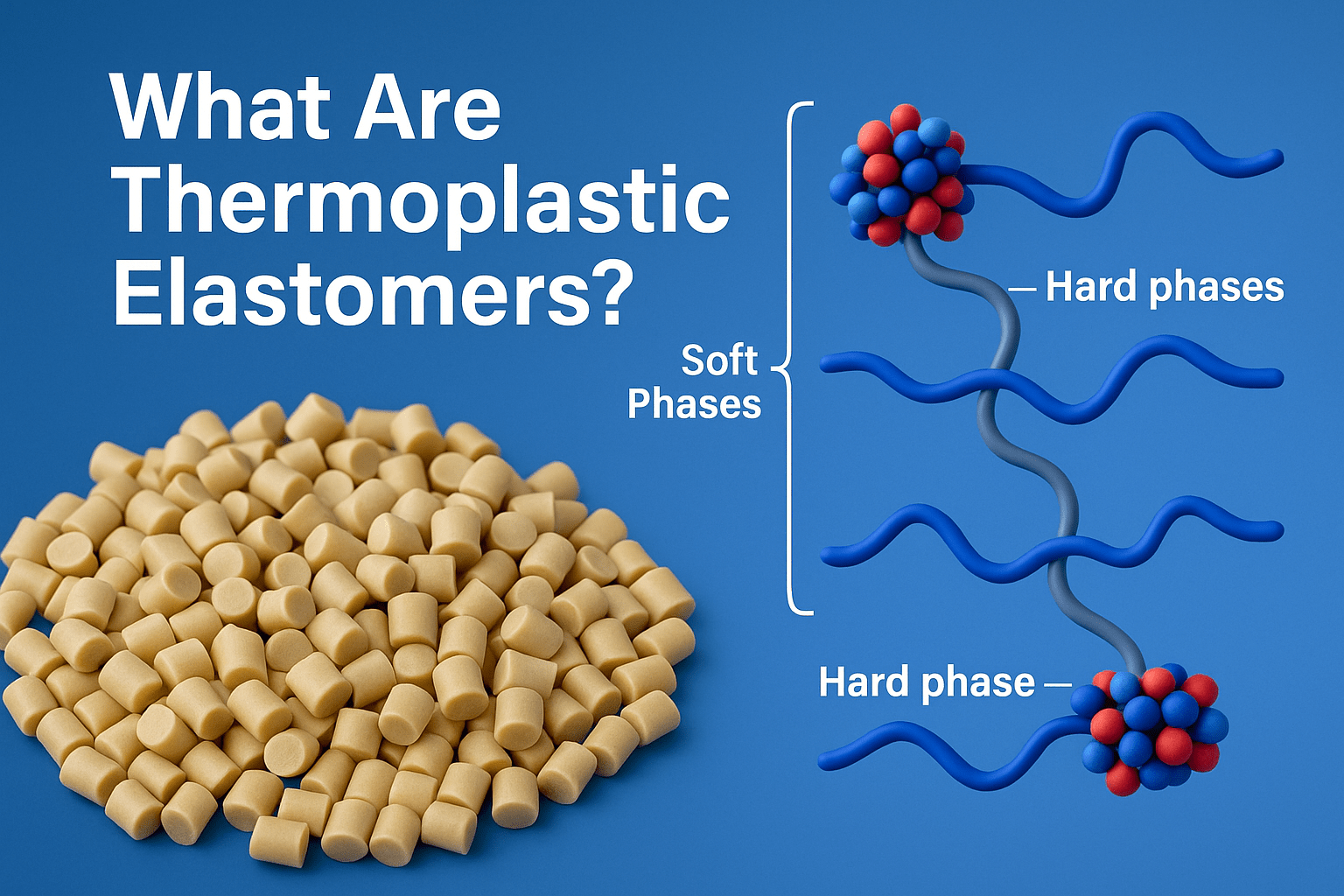

TPE – High-Performance Thermoplastic Elastomer

Advanced Material for Versatile Applications

TPE (Thermoplastic Elastomer) is a high-performance material that combines the elastic properties of rubber with the processability of thermoplastics. It is widely used in various industries due to its flexibility, durability, and excellent mechanical properties.

Key Properties

- Elasticity & Flexibility: Provides rubber-like elasticity while maintaining thermoplastic processability.

- Durability: High resistance to wear, tear, and environmental influences.

- Easy Processing: Can be molded, extruded, and processed efficiently with conventional thermoplastic techniques.

- Chemical Resistance: Offers excellent resistance to oils, chemicals, and UV exposure.

- Recyclability: Eco-friendly material that can be reused and processed multiple times.

TPEs are widely used in industries such as:

Automotive

Found in seals, gaskets, interior components, vibration dampeners, cable insulation, and under-the-hood parts

TPE is commonly used in applications such as automotive components,

medical devices, consumer goods,

and industrial seals, making it a highly versatile material for modern manufacturing.

Agriculture

Used in irrigation systems, seals, protective coatings, and animal care products.

Consumer Goods

Applied in soft-touch grips, toys, footwear, wearables, household items, and appliance components.

Food Packaging

Utilized in sealing rings, flexible lids, bottle caps, gripenhanced packaging, and food-safe tubing.

Construction

Used for window/door seals, roofing membranes, expansion joints, pipe fittings, and tool grips.

Industrial Applications

Found in machine parts, hoses, vibration dampeners, protective coverings, and conveyor belts.

MAK Sohar Chemical Industries LLC specializes in high-performance Thermoplastic Elastomer (TPE) compounds designed for a wide range of applications. Our TPE compounds combine the properties of rubber with the processing advantages of thermoplastics, offering excellent flexibility, durability, and recyclability.

MAKTPS™GP

Our General Purpose TPE-SEBS (Thermoplastic Elastomer – Styrene Ethylene Butylene Styrene) delivers exceptional versatility, making it an ideal choice for a wide range of industrial applications.

MAKTPS™ ST

MAKTPS™ ST is a high-performance TPE-SEBS material engineered to deliver premium soft-touch properties with exceptional bonding capabilities to a

wide range of substrates, including PA, ABS, PMMA, PC.

MAKTPS™ IN & MAKTPS™ EX

Custom TPE-SEBS solutions for automotive interiors and exteriors by MAK Sohar, MAKTPS™ IN is optimized for interior components, while MAKTPS™ EX delivers superior durability for exterior parts.

Dowload our catalogue here: MAK Sohar TPE catalogue

MAKCRP

MAKCRP, which is also known as PE100, is a high-performance High-Density Polyethylene (HDPE) material developed using advanced bimodal technology. It offers superior mechanical properties, crack resistance, and processability compared to standard HDPE.

Advanced Bimodal Technology for Superior Strength and Durability

PE100 Pipe Grade

Key Properties

- High Strength: Excellent resistance to stress cracking and impact.

- Crack Resistance: Superior resistance to rapid crack propagation (RCP) and slow crack growth (SCG).

- Easy Processability: Enhanced flow characteristics for efficient molding and manufacturing.

MAKSPC

Three-layer polyethylene (3LPE) coating is a widely used anti-corrosion protective system applied to steel pipes, typically for use in buried or submerged pipelines, such as those for gas, oil, and water transportation. This type of coating provides excellent corrosion protection and high mechanical strength, ensuring that pipes withstand harsh environmental conditions.

Structure of 3LPE Coating

The three layers in the 3LPE coating system are:

1. Epoxy Primer Layer (First Layer):

- Material: Fusion-bonded epoxy (FBE).

- Purpose: Provides corrosion resistance and excellent bonding to the steel pipe surface.

- Application: Applied directly to the pipe after surface cleaning (typically through sandblasting or shot blasting).

- Benefits: This layer protects the pipe against corrosion and enhances adhesion with the polyethylene outer layers.

2. Adhesive Layer (Second Layer):

- Material: Copolymer adhesive (usually a co-extruded adhesive or grafted copolymer).

- Purpose: Bonds the epoxy layer to the polyethylene outer layer.

- Application: Melted and applied over the epoxy primer.

- Benefits: Ensures strong adhesion between the epoxy and the outer polyethylene layer, providing a uniform and durable coating.

3. Polyethylene Layer (Third Layer):

- Material: High-density polyethylene (HDPE).

- Purpose: Provides mechanical protection against impact, abrasion, and soil stress.

- Application: Extruded as the outermost layer, covering the adhesive layer.

- Benefits: This layer offers excellent impact resistance, protecting the pipe during handling, installation, and operation.

Advantages of 3LPE Coating

- Enhanced Corrosion Resistance: Protects steel from moisture and contaminants.

- High Impact and Abrasion Resistance: Reduces the risk of damage during transportation and installation.

- Good Thermal Resistance: Performs well at varying temperatures.

- Long-Term Performance: Provides a lifespan of several decades under proper conditions.

- Environmental Stress Resistance: Can endure mechanical stresses from the surrounding environment.

Let's be in Touch

Any Questions? We've Got You Covered!

For your convenience, you can download our Technical Data Sheets from our website. If you can’t find what you need, please fill out the following form, and a representative will reach out to you.

A Few Steps to

Get our Products in Your Hands

Inquiry

Begin by reaching out to us using our "Get a quote" page with your specific product needs or questions. Our team is ready to assist and guide you through the process.

Expert review and feedback

Our experts will carefully review your inquiry and provide tailored feedback or recommendations based on your requirements.

Sample Provision

To ensure the perfect match, we will provide a sample of the product for your review, allowing you to assess its quality and suitability.

Delivery

Once everything is approved, we’ll set a convenient time and date for delivery, ensuring your product arrives promptly and in perfect condition.