Thermoplastic elastomers (TPEs) are modern polymer materials that combine the

elasticity of rubber with the processing benefits of plastic. Unlike thermoset rubbers,

TPEs can be repeatedly melted and reshaped, making them more sustainable and

cost-effective in production.

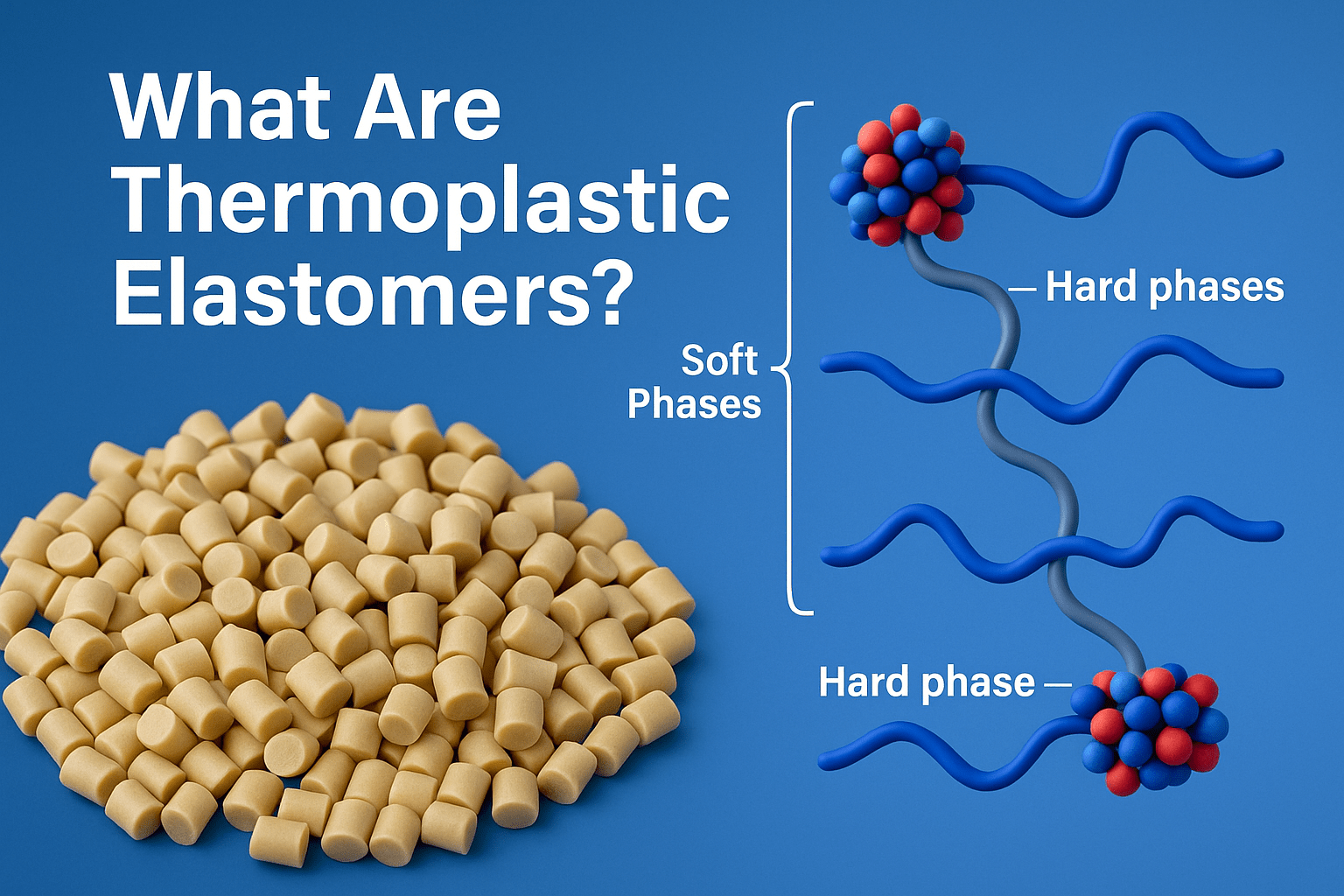

Their internal structure features alternating soft and hard phases, allowing for efficient

shaping through injection molding, extrusion, and other thermoplastic techniques.

Their properties, mechanical strength, flexibility, and chemical resistance—can be

customized to suit different applications.

TPEs are used in a wide range of industries, including automotive interiors, medical

tubing, soft-touch grips in consumer products, and flexible electronics housings. They

are also highly compatible with overmolding, allowing soft and rigid materials to be

combined in a single part.

Available in several types such as TPE-S, TPE-U, and TPE-V, each variant delivers

specific advantages for performance, durability, and environmental conditions.

In summary, TPEs offer an ideal solution for applications requiring durability, flexibility,

and efficient manufacturability, making them essential in modern product design.